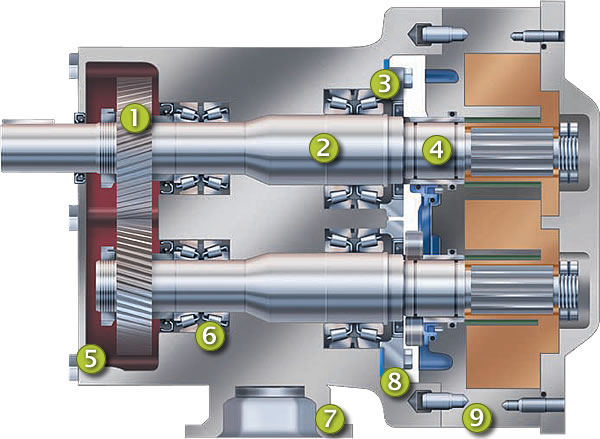

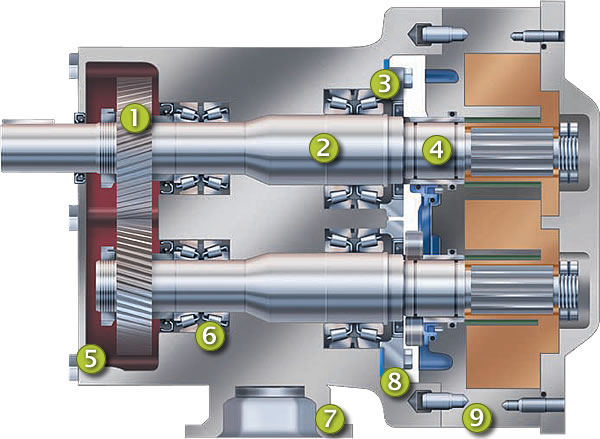

Wright Pump TRA10 Features

TRA10 Features

- Time tested and proven circumferential piston design.

- Exceptional engineering and manufacturing quality.

- Parts interchangeable with other major CPP manufacturer's pumps. Contact BestPump for details.

Design Features

- Helical timing gears reduce noise for quieter operation.

- One-piece, stainless steel shafting (316L on smaller pumps, high strength 17-4PH on larger) ensures strength and stability.

- Stainless steel bearing retainers prevent corrosion and provide easy bearing access and adjustment by shimming.

- A variety of seal options allows the pump to be easily adapted to changing conditions of service.

- Separate oil chamber for the timing gears.

- High performance ball bearings on models 0060, 0150, 0180 & 0300, or high performance tapered roller bearings on models 0450, 0600, 1300, 2200 & 3200.

- The pump housing allows four different installation positions, simply by moving the mounting foot.

- Forward bearings are protected from high fluid temperatures by the cooling air space between the pump head and gear case. This space also allows visual inspection of seal integrity.

- Pump housing and cover made of Type 316 Stainless Steel with 3-A standard finishes. Optional clearances for hot and shear-sensitive liquids available.

Added Value Features

- One-piece stainless steel shafts instead of welded bi-metal.

- Helical timing gears instead of spur gears.

- Silicon Carbide / Silicon Carbide seals instead of Carbon / Ceramic.

- Powder coated casing (FDA white, RAL 9003), instead of painted iron.

- Pump housing dowel pinned and bolted to gear case (instead of dowel pinned only) to protect seals on disassembly and simplify cleaning.

Unique Cleaning and Maintenance Features

- Designed for easy strip cleaning, the pump casing is independently fastened to the gearbox to prevent damage to the seals when the cover is removed, and to allow the rotors to be turned while spraying down the fluid chamber.

- Bearing retainers are stainless steel, not carbon steel, ensuring longer life under harsh cleaning conditions.

- Grease fittings are threaded, not pressed in, to prevent accidental removal during greasing.

Copyright © 2000 - 2012 BestPump Ltd.